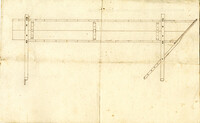

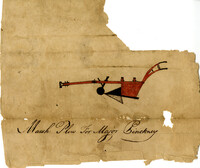

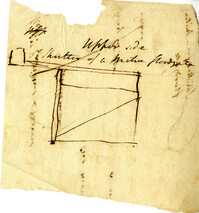

Bernard's patent threshing machine

Close Viewer

- Title:

- Bernard's patent threshing machine

- Date:

- 1808

- Collection Title:

- Thomas Pinckney papers, ca. 1790-ca. 1825.

- Contributing Institution:

- South Carolina Historical Society

- Media Type:

- Manuscripts

- Series:

- South Carolinians at Work

- Personal or Corporate Subject:

- Pinckney, Thomas, 1750-1828

- Topical Subject:

- Drafting and industrial drawings, Mechanical drawing, Agricultural instruments, and Agricultural machinery--Design and construction

- Geographic Subject:

- Berkeley County (S.C.)

- S.C. County:

- Charleston County (S.C.)

- Language:

- English

- Date Digital:

- 2011-11

- Internet Media Type:

- image/jpeg

- Copyright Status Statement:

- Digital image copyright 2011, The South Carolina Historical Society. All rights reserved. For more information contact The South Carolina Historical Society, 100 Meeting St., Charleston, SC 29401.

- Admin ID:

- 47336

Permalink